Selecting the Right Twin-Screw Extruder Screw Configuration Ensures Stable Mixing and Dispersion of Carbon Fiber-Reinforced PA6

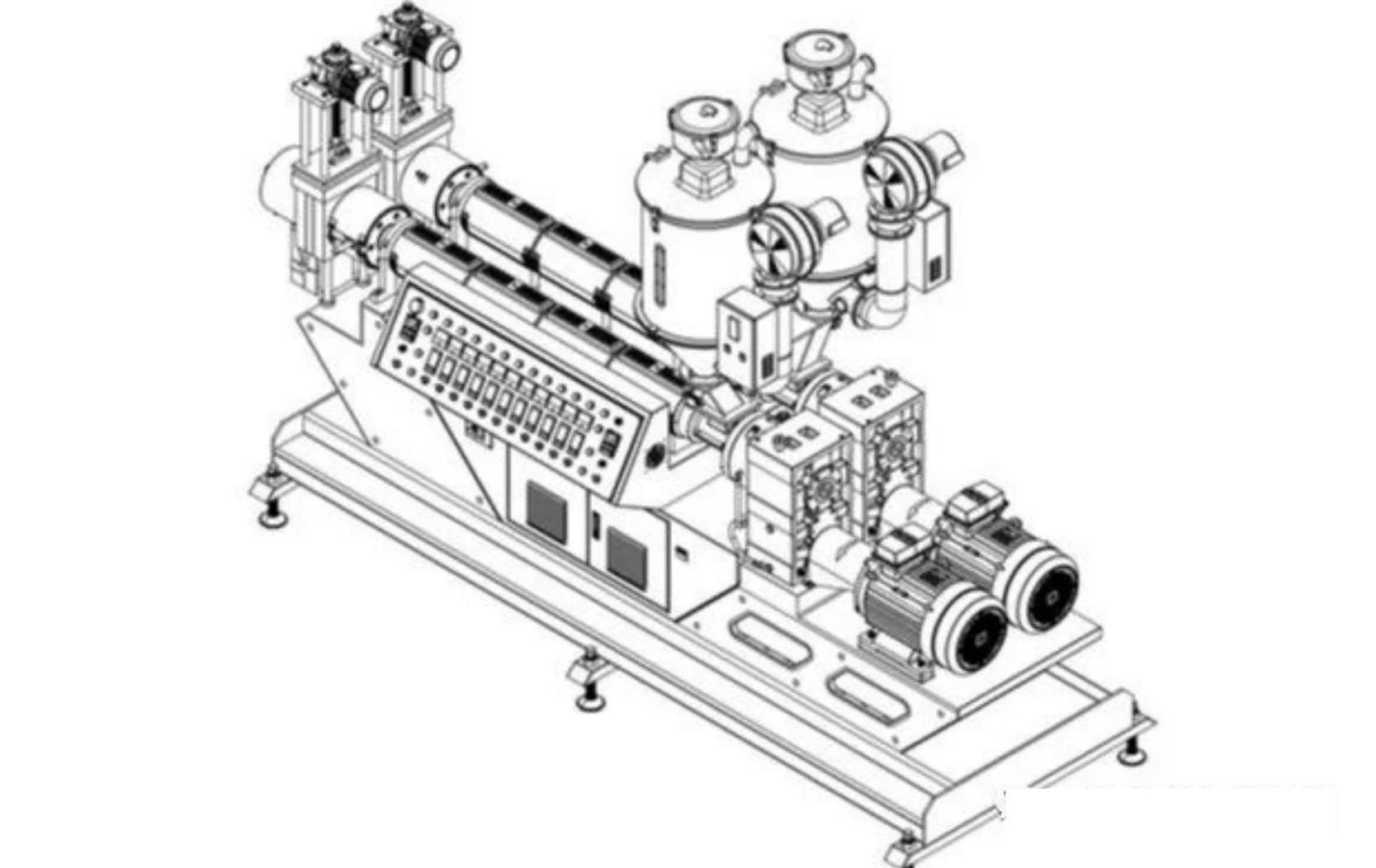

Carbon fiber-reinforced polymer matrix composites are widely used in aerospace, medical, automotive, and shipbuilding industries due to their advantages such as low density, high stiffness, superior strength, and heat resistance. Twin-screw extrusion technology stands out as the primary method for preparing carbon fiber-reinforced polymer composites, owing to its excellent mixing performance, self-cleaning capability, high output, and low energy consumption. Additionally, as injection molding and compression molding techniques become more advanced, the melt produced by twin-screw extrusion can be molded into